CNC Turning

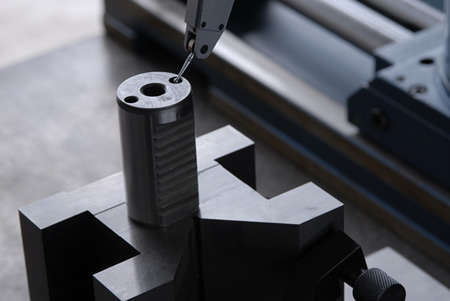

In the process of CNC turning, parts are manufactured by the precision cutting of material as it is turning.

Svemek is using the most sophisticated CNC turning centers for the production of precision machined components from small to medium sized series with tolerances of H7.

The CNC turning centers are 2 and 7 axis.

Our turning centers are able to optimally manufacture minimum dimensions of 10mm and maximum dimensions of 500mm with Ǿ250мм.

CNC Milling

During the process of CNC milling, the parts are machined from solid materials in horizontal and vertical form, depending on the orientation of the spindle.

Svemek possesses the most sophisticated CNC vertical and horizontal machining centers for manufacturing of parts according to precise specifications. The CHC milling machines are used for fast and precise manufacturing.

The CNC machines are 3 - 5 axis centers.

The 3 axis milling machine dimensions for manufacturing:

The 5 axis machine dimensions for manufacturing:

“Multitasking” machine centers

Manual machines

Materials used for production

Different types of: